Why do you need to measure static pressure? None of the other contractors who quoted me a new system have taken measurements. Can’t you just add more refrigerant?

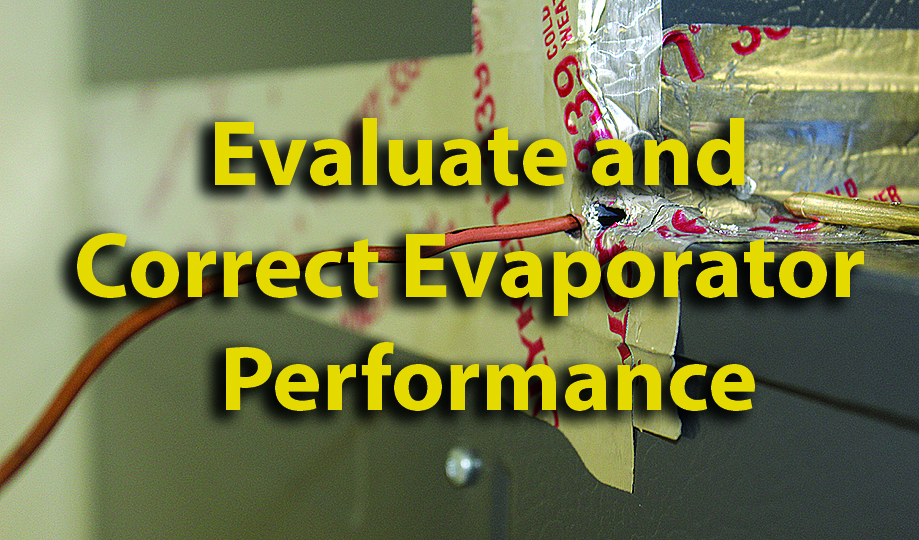

Does this sound familiar to you? Have you ever felt lost as to where to start when a customer’s system does not provide comfort? Static pressure testing can quickly give you insight into how poorly the system is performing.

It also provides some talking points to discuss with your customer. Evaporator coils and filters tend to be the biggest contributor to excessive total external static pressure (TESP).

Effects Of High Coil Pressure Drop

As pressure drop across the coil increases, the amount of energy required to move a volume of air across the evaporator also increases. For modern furnaces with electronically commutated motors (ECM), this means the Watt draw will increase as the motor attempts to overcome the pressure due to their variable operation. As the motor consumes more energy, it decreases the equipment’s Energy Efficiency Ratio (EER).

In older systems (which make up the bulk of motors still in use today), the Permanent Split Capacitor Motor (PSC) operates at a fixed speed. As static pressure increases, airflow decreases. Reducing airflow across an evaporator can lead to a variety of issues.

For example, on the refrigerant side of the system, technicians often misdiagnose low airflow as an undercharged refrigerant circuit.

They are only looking at pressure-temperature relationships. Insufficient airflow can also cause register airflow to fall below the required heating or cooling capacity to the point that customers notice temperature differences between rooms.

High coil pressure drop also impacts the longevity of major system components, such as the compressor or heat exchanger. Under low airflow conditions, inadequate heat is available to convert all the liquid refrigerant to vapor, allowing liquid refrigerant to enter the compressor. In heating mode, low airflow will increase the temperature rise of the heat exchanger.

If a system is allowed to cycle on and off because of excessive temperature, the result is often a crack in the heat exchanger. Whether in heating or cooling mode, airflow depends on a coil with a pressure drop that matches the original design.

Click Below for next page:

Recent Comments