Safer Indoor Air Systems Help Prevent COVID-19

By: Sheila Dunn

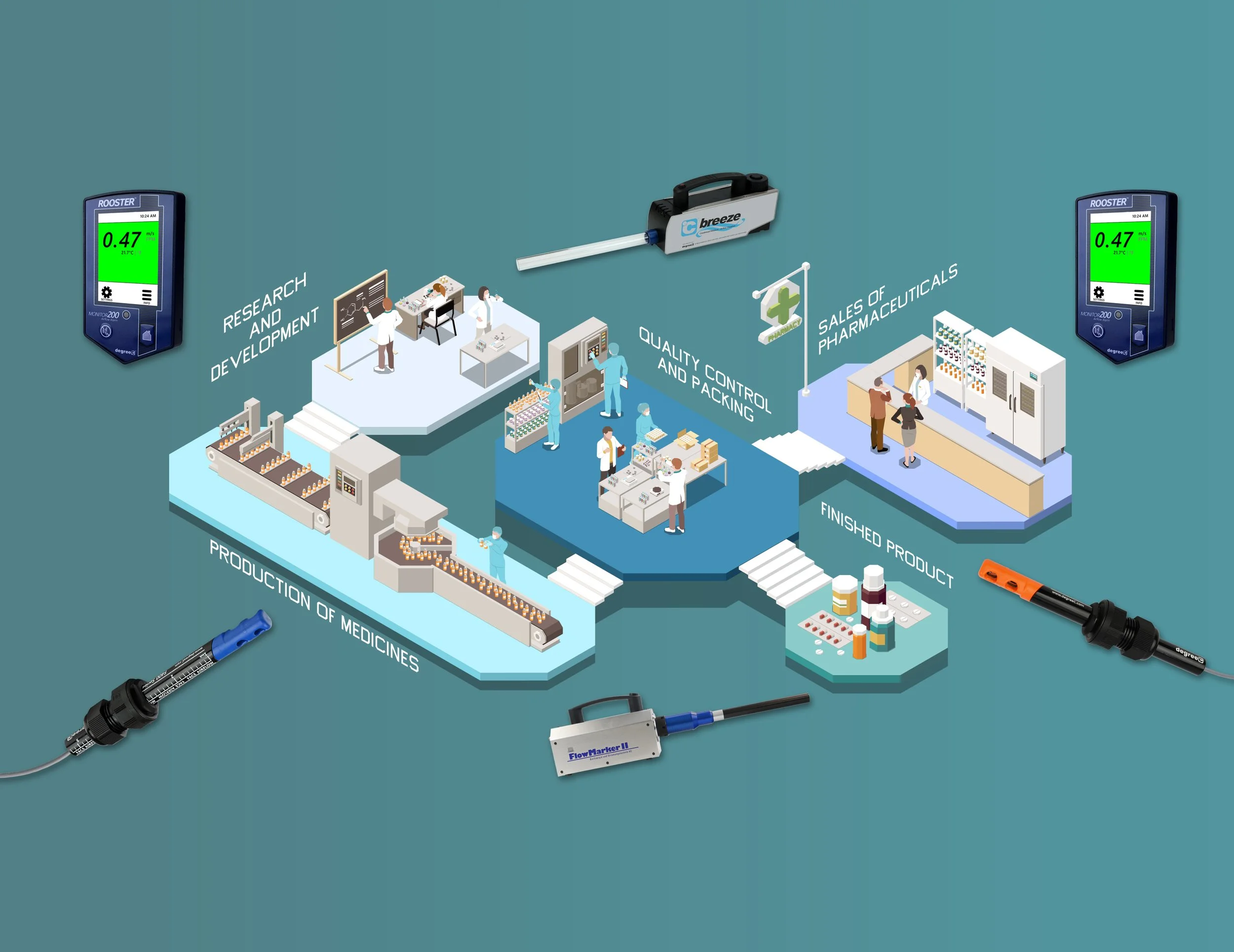

In facilities like pharmaceutical labs and even restaurants, various instruments are required to verify, control, and monitor airflow for a safe indoor environment.

DEGREE CONTROLS, INC. COMPOSITED IMAGE

Airflow is vital for the safety and comfort of building occupants, energy efficiency, and extending the life of buildings and building components. The COVID-19 pandemic has served to highlight the importance of airflow as well as anemometers and airflow measurement and monitoring tools to keep people safe and minimize hazards. Ventilation systems around the world are being evaluated and improved with a focus on health measures and indoor air quality.

Making space for patient care

As a result of the COVID-19 pandemic, hospitals are implementing increased patient capacity by making additional spaces for patient care. Maintaining these rooms or spaces at negative pressure is critical to ensuring safety of surrounding areas and minimizing cross-contamination.

Available air pressure monitor and alarm systems can verify negative pressure prior to placing a room into service and provide continuous monitoring of the room thereafter. These units can be integrated into a laboratory or building management system and designated users can configure alarm set points and output behavior. The ideal monitor displays real-time air pressure and conveys safety by updating the color of the background screen. Critical alarms are augmented with a blinking LED. In addition to air pressure and pressure mode, the system monitors and displays temperature and relative humidity, and features data logging export via the built USB port for your documentation and compliance record keeping.

Airflow for health and well-being

There’s a lot we don’t yet know about COVID-19—however, the CDC, ASHRAE, and OSHA agree that engineering controls are an effective means of protecting employees and communities. Engineering controls are methods built into the design of buildings, equipment, or processes to minimize hazards, and one of the strategies is to remove hazards through air ventilation:

Ensure appropriate air-handling systems are installed and maintained

Ensure engineering controls function as designed

Improve engineering controls using the HVAC system

Consider increasing ventilation rates, and adding technology such as airflow monitoring and alarms, as you review your ventilation systems

There are a variety of airflow safety products available to check and monitor these engineering controls, as well as air velocity, temperature, and humidity sensors for embedded applications. These include:

Switches to alarm when airflow falls below a safe level

Air velocity and temperature sensors to send analog/digital outputs to building ventilation and control systems

Custom fan control solutions, which can connect directly to your larger building control systems

Alarms and monitors for airflow or zone pressurization, temperature, and humidity

Visualization products to verify airflow patterns, detect leaks, and test air filters

Ventilation for safety—minimum ventilation rates for spaces

Recent guidance from ASHRAE is to consider increasing ventilation rates to help protect against the transmission of COVID-19—as a result, many are working to become familiar with an unfamiliar topic. Ventilation is the intentional and controlled introduction of outdoor air into a space. It can improve air quality by diluting and displacing hazards, and also affects the temperature and humidity of a space and direction of airflow within the space. Section 6 of ASHRAE Standard 62.1 provides minimum ventilation rates for spaces including classrooms, restaurant dining rooms, health clubs, and more. The rates consider contamination sources originating from building occupants and their activities, as well as from the building itself. This reference for determining outdoor airflow requirements illustrates how outdoor air rates vary with type of occupancy, density of occupants within the space, and the floor area of the space, and helps us to gain insight into increasing ventilation rates.

Increasing ventilation

Clean, fresh air is generally a good thing, although outdoor source pollutants must be considered. Suggestions for increasing ventilation rates include:

Check and clean your ventilation system

Increase total supply air, and outdoor air, by opening diffusers or adjusting dampers

Run systems longer. Temporarily scale back the use of energy conserving demand-controlled ventilation

Add hardware. An air-side economizer, for example, can bring cool, outside air into a building and distribute it. If your building doesn’t have a ventilation system, opening windows and decreasing the number of occupants in the space are options, in addition to increasing natural ventilation through larger openings

Airflow awareness

Measuring and monitoring airflow will allow you to understand your existing ventilation system, record changes as ventilation systems are adjusted and improved, and discover ventilation issues quickly, as they occur. Standard airflow measurement techniques can be used for measuring outdoor air intake. Install air velocity and temperature probes at key points in your ventilation system to provide real-time feedback to your controller or control system. Get further assurance that target air volume is being added to/removed from a space by installing an airflow monitor for real-time display of air changes per hour (ACH). Unintended flow reversals can also be quickly detected with a bi-directional sensor to output airflow direction, along with air velocity and temperature, in real-time. Measuring velocity in turbulent air can be simplified by using handheld visualization tools to disperse fog into the environment. When the airflow paths are understood, measurement tools can be deployed.

ASHRAE statements regarding transmission of SARS-CoV-2 convey that ventilation and filtration provided by HVAC (heating, ventilating, and air-conditioning) systems can reduce the airborne concentration of COVID-19 and thus lower the risk of transmission. HEPA (high efficiency particulate air) filters are air filters designed to stop or capture very small particulates from an air stream at a highly effective rate. According to the U.S. Department of Energy, to qualify as HEPA, a filter must remove at least 99.97 percent of particles when tested with an aerosol with a size of 0.3 microns.

Airflow and airflow sensors for indoor air quality

Airflow and air velocity sensors play a major role in indoor air quality and air filter selection, operation and performance:

Filtration efficiency, or the ability of the filter to remove contaminants from air passing through the HVAC system, is a big factor in filter selection. HEPA filter test standards establish efficiency under a specified air flow, and this data is included in manufacturer’s specifications.

Filters should be used at their rated pressure drop and face velocity to be most effective. Filter face velocity is the measured air velocity entering the filter, and the pressure drop of a filter is a measure of its resistance to airflow through it, given for specific face velocities. Rated pressure drop increases with air velocity.

Although there are HVAC situations where increased airflow is beneficial, HEPA filters may experience a decrease in collection efficiency if they are operated at a face velocity exceeding manufacturer's specifications.

Conduct periodic and quantitative airflow testing

Airflow sensors embedded in HVAC systems help to ensure that HEPA filters are used at their rated pressure drop and face velocity.

ORIGINAL ILLUSTRATION BY DEGREE CONTROLS, INC.

The control of airborne particulates is dependent upon many factors which include filter efficiency, air velocity and airflow uniformity. Airflow measurement and monitoring will allow you to identify any variations that might adversely affect filtration and system performance and thus increase the risk of contamination. Single or multipoint air velocity sensors should be used to measure face velocity across filters and verify flow at strategic points in the system. Airflow visualization products should be used to verify airflow patterns and identify turbulence which may negate the clean spaces you’ve worked so hard to establish. Handheld foggers are portable, easy to use and show real-world airflow patterns immediately.

Measuring air velocity and analyzing air patterns for safety

We are not alone in our support of the use of airflow management tools for engineering controls, as well as airflow visualization products to verify airflow patterns and identify turbulence in indoor environments such as restaurants, classrooms, and manufacturing facilities. FDA guidance discusses the importance of clean areas for drug product quality and includes recommendations for measuring air velocity, as well as in situ air pattern analysis at critical product areas. As scientists around the world work on potential treatments and vaccines for COVID-19, the FDA continues in its oversight of drug and vaccine production and monitors manufacturers with its Current Good Manufacturing Practice (CGMP) regulations for ensuring quality and safety.

Foggers are easy to use and a good first step in understanding the airflow conditions of your indoor space. Smoke studies show airflow direction and uncover areas of turbulence and stagnant flow. Smoke study videos demonstrate and document the airflow characteristics and provide an effective means of communication and collaboration in your work to establish and maintain safe indoor air systems.

The inclusion of aseptic techniques in dynamic smoke studies is an important factor in maintaining control and preventing contamination in pharmaceutical drug production, however the use of handheld, portable foggers for airflow visualization is universal. Restaurant owners, facilities managers, sterile drug compounders and others all find value in the fast, effective results delivered by our foggers. Smoke generators are used for initial assessments of airflow patterns and also serve as key companions to air velocity sensors and airflow monitors in verifying ventilation systems and ensuring that they operate as designed.

Airflow measurement to validate CFD analysis

The coronavirus (COVID-19) pandemic is affecting all of us. As the world works toward reopening, simulation is one of the strategies being used to understand ventilation systems and how aerosols and droplets propagate. This allows managers of indoor (and outdoor) spaces such as offices, manufacturing facilities, restaurants, and lecture halls to better prepare and prevent the transmission of COVID-19. Validation of CFD modeling with air velocity, temperature and humidity sensors ensures prediction quality. HVAC and ventilation systems can vary widely, and airflow sensor placement strategy varies by application. Other airflow tools which are used to collect quantitative information include:

Sensor pole arrays are devices with multiple air velocity sensors along their length. By mounting the pole array to a telescoping base, users can take readings at different heights and create an X-Y planar airflow analysis in a room. This technique is also useful for evaluating thermal stratification and the effectiveness of mixing air to achieve temperature equalization in your space.

Grid arrays are pre-built, X-Y sensor arrays contained in a frame, used to study the planar airflow profile in room areas, ducting, HEPA filtration units, and airflow dampers. Grids arrays are built with up to 200 sensors, each measuring air velocity and air temperature simultaneously. Experiments using a grid array at multiple locations can resolve 3D airflow plumes.

A series of individual airflow, temperature and humidity sensors can be connected together with a data acquisition instrument and datalogging software, which enables the user to position the sensors to create custom, multi-point sensing arrays. This solution is used around the globe for determining airflow patterns and velocity and temperature distributions.

Sheila Dunn is an applications engineer with Degree Controls, Inc. and assists engineers and technical professionals in the development and support of airflow solutions for laboratory, building, and industrial safety applications. Sheila has worked in the high-tech industry for 20+ years, holds a BS in electrical engineering, and is an inventor on several US patents. Sheila has a high appreciation for technology and innovation and helping customers develop better products using the latest airflow technologies.