In the shadow of the Queensboro Bridge, on New York City’s Roosevelt Island, three buildings now under construction will together form the core of a new technology campus for Cornell University. The tallest of them, a student and faculty residence, will look much like any number of apartment towers going up around the city. In fact, it was designed to be one of the most energy-efficient high-rises on the planet.

The 26-story building is the work of Handel Architects, a New York–based firm that in 2011 partnered with developers and engineers to compete to design a residence on the new campus. Together they put forward an ambitious proposal: a building that would meet the most rigorous energy-efficiency standard in the world, called “passive house.” Not only that, it would be both the tallest and the largest passive-house building in North America, if not the world.

Launched in Germany 25 years ago, passive-house construction remains uncommon in the United States, where it is mostly confined to one-off, self-consciously innovative homes, such as the R-House in Syracuse, New York. The standard takes its name from its core principle: that instead of relying on active, energy-sucking technologies to stay warm or cool, a building ought to “passively” remain comfortable, through design and construction. By effectively retaining heat in winter and keeping it out in summer, passive-house structures consume a fraction of the energy used by otherwise comparable buildings.

Passive-house architects tend to rely on several basic strategies: Position the building to capture steady southern sun; design a compact shape with a minimal exterior surface area; insulate and seal the whole thing snugly; and install super-efficient windows and ventilation. On the first and second counts, Handel got lucky. The site’s orientation and oblong shape provide a long southern exposure. And because the building is to be divided into 352 apartments, it will have a high ratio of interior to exterior walls.

Insulating and sealing the 285-foot-tall tower will be trickier. “You’re essentially trying to create a cooler out of your building, where the insulation wraps all the way around,” says Lois Arena of Steven Winter Associates, a consultant on the project. The building will have a highly insulated, supertight wrapper ranging from six to 11 inches thick. So that it wouldn’t resemble a bulky coat, the architects angled the wrapper to make it a highlight of the design. It starts on the southern facade, reaches its peak at the southwest corner, then folds all the way around the building and back across the southern facade once more. It will ultimately have an outer coating of metal, with deeply recessed rows of windows creating a series of prominent horizontal bands. At the bottom of the southern facade, the wrapper lifts to form an angular canopy over the building’s main common area.

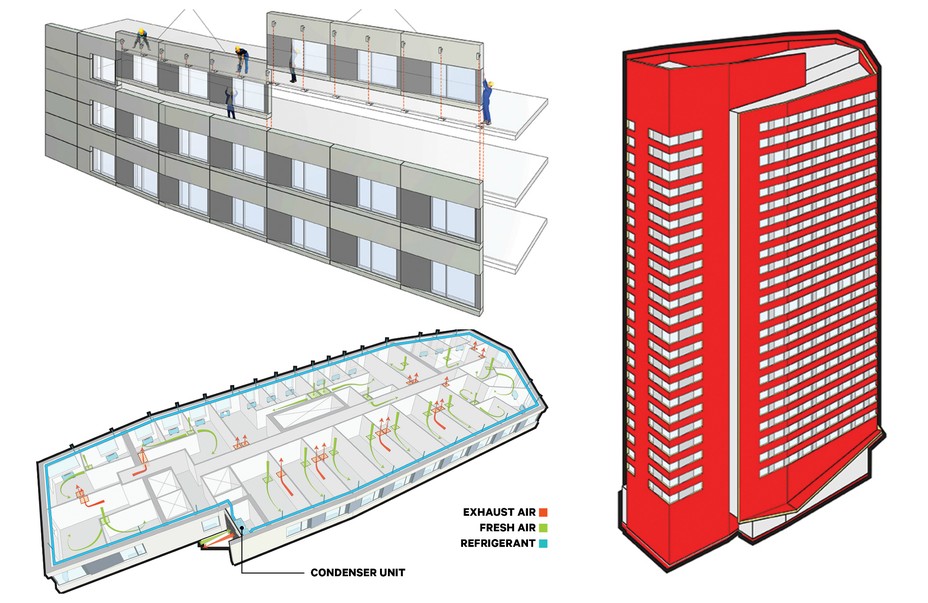

In conventional apartment buildings, fresh air leaks in through the windows and main walls, while exhaust ventilation pulls air out of the kitchens and bathrooms. But in this airtight building, fresh air will flow through ducts into each of the apartments, and exhaust air will flow out through separate ducts. Up on the roof, two energy-recovery units will extract heat from the exhaust air and transfer it to the incoming fresh air, dramatically reducing the amount of energy needed for heating. On each floor, refrigerant will flow through a condenser on a balcony into the apartments, where residents will be able to adjust temperatures. This kind of system, more common in Europe and Asia, saves energy by operating at a variable, rather than constant, speed.

As the building’s frame goes up, off-site workers are beginning to assemble its walls out of 36-foot-long prefabricated panels—sandwiches of metal, insulation, and triple-glazed windows, with various brackets and clips to hold everything in place. The joints where panels meet one another and the floor present one of the biggest opportunities for heat loss. To head off this risk, the designers devised an intricate system of plastic-membrane flaps and tape to seal the joints. They are teaching their taping method to contractors, one example of how the project aims to serve as a demonstration.

When the residence opens in 2017, it is expected to use just 25 percent as much energy as a typical apartment building of the same size. In the meantime, as local builders, tradespeople, designers, and developers learn more about the passive-house approach, the architects hope it will start to catch on. Gary Handel, the firm’s founding partner, likens the project to a snowplow clearing the road: “It’ll be a lot easier to follow behind,” he says.