By Chris Wolgamott, CEM and Teddy Kisch, LC

From the April 2021 Issue

Since the start of the COVID-19 pandemic, facility managers and owners have faced several challenges, from navigating security and maintenance issues with an increasingly remote workforce to adapting to changes in how and when spaces are used, all while working to control operational costs. The pandemic has also placed greater emphasis on the importance of health and safety in commercial buildings. Access to more granular data and increased flexibility can help facility managers and owners better deal with these types of disruptions as the world of commercial spaces continues to evolve. Connected lighting systems are one potential solution that offer both robust data and enhanced flexibility.

Luminaire Level Lighting Controls, or LLLC, are a subset of networked lighting controls. In an LLLC system, each individual light fixture has its own built-in sensor, enabling them to communicate and transmit data wirelessly. With LLLC you can group and regroup lighting as needed, all the way down to the individual fixture level.

LLLC is generally seen as a tool for energy efficiency and cost savings, which vary by facility type and hours of operation but are significant, averaging up to 63% beyond fixture upgrade savings alone. This is achieved by “layering” different control schemes, like occupancy sensing and daylight harvesting. However, LLLC technology also offers an array of benefits beyond energy savings. With many systems, these business benefits can include integration with other building systems (e.g., HVAC, asset tracking, integrated security). Given that cost is often a key deciding factor when installing or retrofitting a building’s lighting system, these benefits can often tip the balance and even outweigh the energy savings LLLC offers.

On the topic of costs, a new study shows another positive development for LLLC technology. Over the past three years, costs have seen a continued downward trend.

The “2020 Luminaire Level Lighting Controls Incremental Cost Study,” funded by the Northwest Energy Efficiency Alliance (NEEA), annually tracks the cost of LLLC fixtures compared to fixtures with no controls, based on “all-in” costs for equipment and labor from purchase through installation.

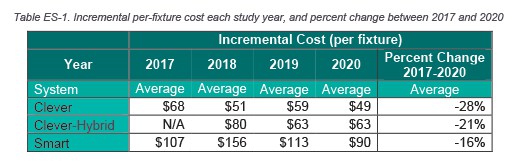

In the 2020 study, researchers from Oakland, CA-based Energy Solutions interviewed a total of 16 manufacturers and manufacturer representatives to collect detailed labor and other cost data across 19 lighting projects based on prototypical office buildings. As shown in Figures 1 and 2, the study found that between 2017 and 2020, the per-fixture incremental cost of the most basic LLLC fell 28%, from $68 in 2017 to $49 in 2020. The 2020 total cost per-fixture was $149 vs. $100 for a standard LED fixture without controls. Over the same period, the per-fixture incremental cost of advanced LLLC with added features also fell by 16%.

Published in January 2021, the study classified different LLLC systems into three categories: clever, clever-hybrid, and smart.

Clever systems meet basic requirements of the DesignLights Consortium (DLC) Qualified Products List (QPL), such as high-end trim, dimming, occupancy sensing, and “plug and play” fixtures with little or no additional programming costs upon installation.

“Smart” systems include all “clever” capabilities but can also analyze and communicate both energy and non-energy data to inform decision-making processes for a wide variety of Internet of Things (IoT) use cases, such as space utilization, HVAC optimization, and retail asset tracking.

An emerging product subcategory is “clever-hybrid” systems that fall between smart and clever: these include a standalone gateway and provide additional functionality, such as energy monitoring, yet lack the full IoT capabilities of a smart system.

Overall, the study showed the incremental cost of installing LLLC versus LED lighting without controls varies by $40-90 per fixture across the different system categories. While not insignificant when multiplied across all the fixtures in a facility, many utilities also offer substantial incentives for installing LLLC. For example, in the Pacific Northwest, some utility incentives can be as high as $75 per fixture or even higher in some cases. It’s worthwhile to check what your local utility offers before making a decision about your lighting system, since once incentives are factored in there may essentially be no or very minimal cost difference between LLLC and traditional LED lighting.

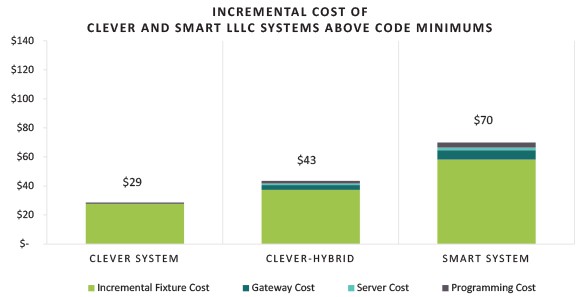

The study also compared the cost of an LLLC fixture to a fixture with standard code-compliant controls (rather than to a fixture with no controls as discussed earlier). Here the incremental costs range from $29-70 per fixture (because the code minimum controls cost about $20, lessening the cost difference).

The incremental costs are shown in Figure 3. Also shown is that the cost of the fixture with its integrated sensor and controller makes up the largest percentage of the total per-fixture costs. The per-fixture costs of the gateway, server, and programming are relatively small in comparison. Taken together, these elements enable LLLC to provide greater value to facility managers and owners than standard controls.

For example, an individual LLLC fixture can transmit data on fixture energy usage and performance metrics, which allow predictive maintenance through diagnosis and automatic e-mail notifications to identify potential issues before they occur. Each LLLC fixture has an occupancy sensor—these can be activated to provide more precision in sensing intruders and notifying security teams. LLLC fixtures can also have thermal sensors that can be integrated with fire and life safety systems to create unique alarm responses, such as “pulsing” lights showing the egress path away from hot spots identified via the thermal sensing. Recently, LLLC sensors have also been used to support COVID-19 related contact tracing. Some retailers are even using LLLC to understand traffic flow in stores to optimize sales and send tailored marketing offers based on a customer’s location.

While the capabilities of LLLC may seem somewhat futuristic, the technology is by no means new or untested. All major lighting manufacturers offer LLLC products, making these relatively easy to find. These have also been successfully installed and leveraged across a wide range of building types from large healthcare centers to offices and even massive warehouses run by familiar retail names like Costco and IKEA. Additionally, all the LLLC equipment used in the recent NEEA study was well-vetted, having met all DLC Qualified Products List requirements, and was representative of the range of options available on the market today.

Currently, connected lighting comprises less than one percent of all luminaires in the U.S. Based on what we’ve seen with the downward trend in costs and vast expansion of features and benefits, this percentage is likely to grow substantially over the next two decades. The Department of Energy (DOE) estimates that by 2035, almost a third of installed luminaires in commercial buildings are expected to have network connectivity.

The possibilities of LLLC will continue to grow as the industry innovates and introduces new use cases. Considering lighting systems are only updated every 10-20 years, when investing in LLLC technology today, facility managers and owners are able to “futureproof” their buildings and gain flexibility to adapt to the needs of tomorrow.

Wolgamott is senior product manager at the Northwest Energy Efficiency Alliance (NEEA) and has over 20 years of experience in energy efficiency. He is also a Certified Energy Manager and a Certified Demand-Side Management Professional who frequently presents on the future of lighting controls across the country and serves on the Next Generation Lighting Systems’ Connected Lighting Advisory Group.

Wolgamott is senior product manager at the Northwest Energy Efficiency Alliance (NEEA) and has over 20 years of experience in energy efficiency. He is also a Certified Energy Manager and a Certified Demand-Side Management Professional who frequently presents on the future of lighting controls across the country and serves on the Next Generation Lighting Systems’ Connected Lighting Advisory Group.

Kisch, LC is the senior manager of new product delivery at Energy Solutions, specializing in technology evaluation and development of programs that support adoption of high efficiency and low-carbon technologies. He has managed a wide range of lighting studies evaluating LEDs and controls, including a recent evaluation of quantifying energy savings from networked lighting controls.

Kisch, LC is the senior manager of new product delivery at Energy Solutions, specializing in technology evaluation and development of programs that support adoption of high efficiency and low-carbon technologies. He has managed a wide range of lighting studies evaluating LEDs and controls, including a recent evaluation of quantifying energy savings from networked lighting controls.

Do you have a comment? Share your thoughts in the Comments section below, or send an e-mail to the Editor at acosgrove@groupc.com.

Interested in Lighting Products & Controls?

Are you looking for lighting products and controls for your facility? Check out all the latest facility management news.

![[VIDEO] Collect Asset Data at the Speed of Walking a Building](https://facilityexecutive.com/wp-content/uploads/2024/02/maxresdefault-324x160.jpg)