Since the late 1970s, indoor air quality (IAQ) has been increasingly recognized as having a direct effect on the health and well-being of building occupants. Recently, the impact of HVAC systems in the fight against airborne virus transmission has generated a renewed focus on air quality. However, with the introduction of fresh air, improved filtration, humidity control, and other air treatment methods comes a growing concern about the potential for higher system loads – and the increased energy use that can result. Fortunately, the proper application of modern HVAC technologies can help maximize indoor air quality while minimizing losses in operational efficiency.

The Indoor Air Quality Challenge

A little over four decades ago, a phenomenon called “sick building syndrome” (SBS) became a concern for both residential and commercial building occupants across the globe. While the exact cause of SBS remains uncertain, there is widespread agreement the issue was rooted in the inability of well-sealed buildings to provide sufficient ventilation for occupants. By 1984, the issue had become so prevalent that the World Health Organization released a 484-page report specifically focused on indoor air quality. Today, we know symptoms of SBS can include dizziness, nausea, headaches, fatigue, eye, nose and throat irritation, and more. And, critically, it is also believed that air cleaning and improvements to building ventilation can be important components of a larger strategy to fight the SARS-CoV-2 (COVID-19) pandemic.

The United States Environmental Protection Agency (EPA) has indicated that the SARS-CoV-2 virus that causes the coronavirus disease may be spread via airborne particles in indoor environments, among other means. One strategy to mitigate virus transmission involves the introduction of fresh, outdoor air. The benefits of fresh air are well documented and understood. For that reason, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 62.1 provides ventilation guidelines to help ensure proper indoor air quality levels are maintained.

Unfortunately, when fresh air is introduced into an HVAC system to improve a building’s air quality, the incoming air must be heated or cooled and humidity levels must be adjusted to meet the requirements of the building or occupied space. At the same time, an equal amount of treated air must be exhausted outside of the building to maintain proper system balance. Both the incoming air treatment and loss of treated air can have a negative impact on an HVAC system’s overall energy efficiency.

Minimizing Fresh Air Energy Loss

In the case of a commercial rooftop unit, there are typically two primary strategies used to minimize the impact of ventilation on energy use: demand-controlled ventilation (DCV) and energy recover wheels (ERWs). A demand-controlled system matches the introduction of fresh air to the actual occupancy of a space but, during the COVD-19 pandemic, DCVs are not an energy-saving solution currently recommended by the Centers for Disease Control and Prevention (CDC). Energy recovery wheels, or counter-flow heat exchangers, do not limit the amount of fresh air brought into a building. Instead, ERWs simply transfer energy between an exhaust (indoor) airstream and an incoming fresh airstream to precondition the incoming air, making it closer to the desired indoor temperature and humidity conditions.

In many applications, an ERW can provide one of the most cost-effective ways to offset energy used in the treatment of fresh air. An ERW transfers energy between an exhaust (indoor) airstream and an incoming (outdoor) airstream, which preconditions the incoming air to be closer to the desired requirements of the occupied space. This entirely passive process can provide significant energy savings and can be used in process-to-process, process-to-comfort, and comfort-to-comfort applications.

The ratio of energy transferred from one air source to the other is known as effectiveness. The total energy transferred by the wheel is the product of the wheel effectiveness, the airflow volumes of the two airstreams, and the difference in energy levels between those airstreams. Using these and other calculations, engineers can determine how much of a reduction in required energy an ERW may be able to provide and may even help a building qualify as “green” in some locations.

Additional Indoor Air Quality Opportunities

While the introduction of fresh air to an indoor space can provide immediate benefits, it is energy intensive. Therefore, increasing ventilation alone won’t solve every air quality challenge. In fact, the EPA estimates the concentrations of some pollutants are 2-5 times higher in outdoor air than indoor air. Dust, dirt, pollen, smog and other irritants are just a few potential contaminants that can cause or otherwise exacerbate existing respiratory issues, allergies, asthma, headaches and other illnesses. IAQ products can help clean indoor air and maintain ideal humidity levels to help reduce irritations and improve occupant well-being. Which solutions are appropriate for a given space will depend largely on the specific needs of the occupants and the intended use of the space – a hospital, for example, will have entirely different IAQ needs than a manufacturing facility. These IAQ solutions may include:

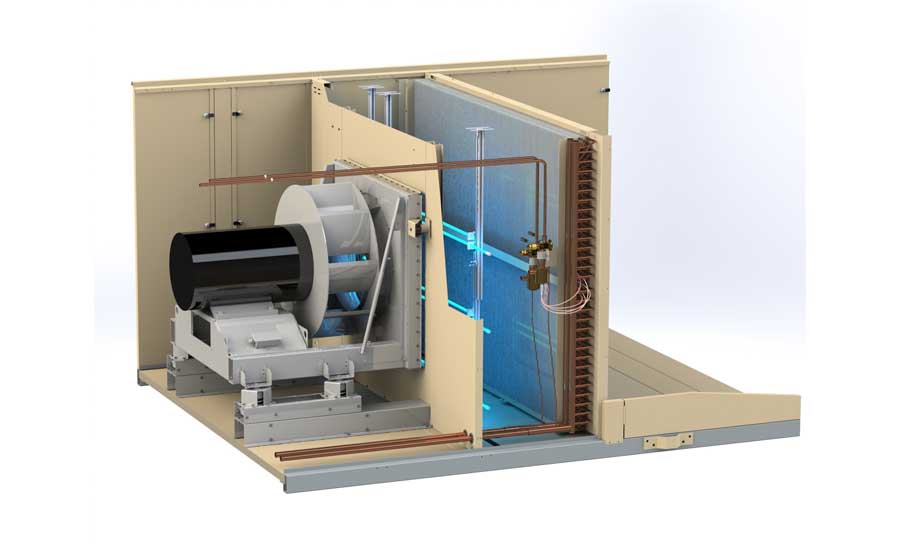

Germicidal UV-C Lights: One of the fastest evolving technologies introduced to the HVAC industry in the past 30 years is ultraviolet disinfection. Using ultraviolet germicidal irradiation (UVGI), these systems can kill or inactivate mold, mildew, dander, bacteria and viruses by using UV-C light (short-wave; 280 to 200 nm) to damage the nucleic acids and proteins of pathogens. As a result, many building owners and engineers are turning to ultraviolet disinfection to meet the new and emerging ASHRAE requirements – particularly in high-density locations. These devices can be mounted in ductwork or air-handing units (AHUs), helping them stay clean and run more efficiently. They can also help combat the mold and bacteria often found in high-condensation areas of system components like the indoor coil.

Click diagram to enlarge (Courtesy of Johnson Controls)

Pre-Filters and Final Filters: In a multi-filter system, a pre-filter catches large contaminants before they reach the more expensive, final filter. This can prolong the life of the final filter and potentially reduce costs. Filters can be found in a variety of minimum efficiency reporting value (MERV) ratings that measure how effectively a filter can stop airborne contaminants. Generally speaking, a higher MERV number equates to better filtration. For example, a residential application might use filters rated at MERV 14, whereas a hospital operating room may require filtration of MERV 17 or higher. While it can be tempting to install the highest MERV rating possible, the smaller pores found in filters with a higher MERV rating can put an increased strain on an HVAC system, causing an increased pressure drop and reducing its overall efficiency. Pre-filters and final filters can be made of a variety of materials, including:

- Fiberglass Filters: Designed primarily to catch large airborne contaminants, spun fiberglass filters are among the most common filters found in A/C and furnace units. While they lack some of the capabilities of other filter types, fiberglass filters are an easy-to-find, cost-effective solution.

- Pleated Filters: While still among the reasonably priced options, pleated filters are more tightly woven than fiberglass and are often a better choice for catching pet dander and dust mites. They also add more resistance to the system and may cause a slight loss in efficiency.

- Electrostatic Filters: Utilizing microscopic cotton and paper fibers that generate a charge when in use, these filters offer the ability to attract more contaminants than less-expensive options.

- HEPA Filters: The high-efficiency particulate air (HEPA) filter is tested to be at least 99.97% effective at removing particulates as small as 0.3 microns and is typically used in hospitals to help reduce the spread of infections. However, like a standard filter with a high MERV rating, the high-density fibers found in HEPA filters can create a strong resistance to airflow and reduce energy efficiency of the HVAC unit.

Bipolar Ionization: This process works by converting oxygen molecules into charged atoms that cluster around microparticles, then surround and deactivate airborne viruses, bacteria, and other pollutants. Modern bipolar ionization techniques don’t involve filters, chemicals, radiation, or other processes that might use excess energy or introduce unwanted side effects. ASHRAE does not currently have a stated position regarding the use of bipolar ionization, which is considered by the CDC to be an emerging technology. The CDC specifically notes that “while the technology has matured … bipolar ionization has a less-documented track record in regard to cleaning/disinfecting large and fast volumes of moving air within HVAC systems.”

Humidification/Dehumidification: It is well understood that higher indoor humidity levels can make a room feel too hot, while lower levels can make a room feel too cold. However, comfort levels are only part of the humidity story. An imbalance in humidity levels can also allow mold, bacteria, and viruses to grow. In fact, new research is indicating proper humidity control may play a role in combating the COVID-19 pandemic. In its April 2020 report, the ASHRAE Epidemic Task Force indicated that “maintaining indoor relative humidity >40% will significantly reduce the infectivity of aerosolized virus” and midrange humidity levels may likewise be associated with improved respiratory immunity.

A Balanced Approach to Energy Efficient Indoor Air Quality

Improving the indoor air quality of a building directly affects the health and comfort of its occupants – and it doesn’t have to come at the cost of energy efficiency. Every building is unique, and every solution should be equally unique. To achieve a balance between IAQ and energy efficiency, an increase in fresh air intake should be offset by appropriate energy recovery methods. Filtration stages should be determined based on occupant needs and system requirements. Strategies to maintain proper humidification must be an integral part of the system design. And newer disinfecting and virus deactivating technologies should be considered as part of a systemwide approach to occupant health and well-being.

Maintaining healthy indoor air quality is more important than ever. Balancing the application of modern HVAC technologies with the needs of occupants, operators, and owners alike, we can improve building air quality while maintaining a high degree of operational efficiency.

Report Abusive Comment